the specific characteristics of industrial oil filtration using wire mesh

In the process of processing petroleum processing, there will be a process of separation and purification. This process is unified as a filtering device. Now, screening, research and production processes of various petroleum and diesel oils are inseparable from a filtration project. It is very important to use the Liquid Filtration Wire Mesh structure for this device. So what are the specific characteristics of the Stainless Steel Mesh For Petroleum screen used for industrial petroleum filtration?

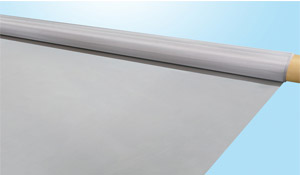

Stainless Steel Mesh For Petroleum

First: To understand the characteristics of industrial oil filtration

When filtering industrial raw materials such as petroleum, the selected mesh should have the following characteristics: wear resistance, flexibility, corrosion resistance, durability, etc., and because of the characteristics of the filter, the current metal mesh In the market, the screen is the best filter product, and according to the parameters of some screens, it has very beneficial value in all aspects.

Second: What types of screens are used to filter?

1. stainless steel wire mesh

Stainless steel wire mesh structure is often seen in all major markets. The main characteristics of this product are filter removal, separation of liquids, etc., used in industrial petroleum filtration, which can produce greater value and become durable copper wire. Net material products, effectively improve oil filtration and purification quality. The stainless steel filter can be divided into plain, twill and dense weave according to the weaving method, wherein the dense mesh includes plain weave - dense grain, twill - dense grain; and various embossing weaving methods. Acid, alkali, high temperature, tensile and abrasion resistance.

2. alloy copper wire mesh

The alloy copper wire mesh is also a relatively common metal mesh. Its mesh density and mesh size are relatively large, and it has the effect of removing dust and dust. The appearance of the product adopts the coating method and has excellent corrosion resistance. It can be used in Industrial oil filtration is the best product.

In general, ordinary mesh belts work hot and brittle at high temperatures, as do stainless steel mesh belts. Stainless steel mesh belts work because of the heat generated by friction. Due to the difference in the manufacturing process, the coefficient of thermal expansion of the stainless steel mesh belt is different. When different materials are welded together, there is a possibility of thermal fatigue. When the ambient temperature exceeds 400 ° C, the expansion of the belt conveyor between the whole machine caused intermittent reduction should also be fully considered. Of course, there is a point that when the stainless steel mesh belt is exposed to inert materials, it will cause undesirable results. First, the stainless steel mesh belt parts will become finer and finer, resulting in accelerated wear. Generally, the rust on the stainless steel mesh belt parts will also affect the rolling. The flexible rotation of the child. I hope that the above introduction can help everyone use stainless steel mesh.

Through various types of analysis of copper wire mesh, it is best to use copper wire mesh products in industrial petroleum filtration, which can meet the various characteristics and functional requirements of the filter in industrial petroleum filtration, and bring very favorable value. Our company Stainless Steel Wire Mesh Supplier, welcome to come and consult.

评论

发表评论