Which Wire Mesh Material Is Suitable for Me?

Stainless steel and nickel are two common materials in numerous industries. Each material has its own set of advantages and disadvantages, which determines which one you consider in the grand plan of things.

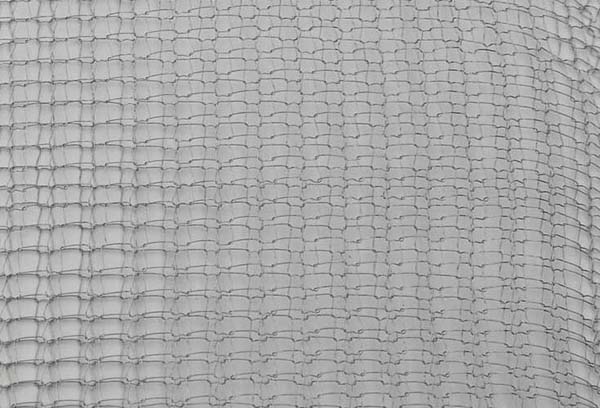

Now, although woven wire mesh is synonymous with stainless steel, it is important to know that other materials such as nickel can also be used to build wire mesh. In other words, it is also important to understand the difference between the two to ensure that you use the alloy that suits you.

We have the necessary expertise to provide you with everything you need to build a screen solution, so you can rest easy.

With this, this article will cover the following points to give you a better understanding of the comparison between stainless steel wire mesh and nickel wire mesh:

What is stainless steel?

What is nickel?

Comparison between stainless steel and nickel.

What kind of alloy suits you?

What is stainless steel?

Stainless steel is a series of alloys with specific carbon and chromium content. The composition of this element makes stainless steel have relatively high corrosion resistance and extreme temperature.

Unfortunately, this high heat resistance makes stainless steel alloys difficult to weld when using some lower temperature welding techniques because they absorb heat.

In other words, in the stainless steel world, there are nine prominent variants: 304, 309, 310, 316, 317, 318, 321, 330, 347. However, in the world of weaving wire mesh, 304 and 316 stainless steel are mainly used.

What is nickel?

Nickel is a natural alloy in the periodic table, which is usually used in special applications where alloys that meet strict standards are required. It is a wire mesh alloy that, like stainless steel, is famous for its high corrosion resistance.

When using braided wire mesh, nickel 200 and Monel (1) alloy 400 are widely used.

How do stainless steel compare with nickel?

When it comes to brass tacks, the difference between stainless steel wire mesh and nickel wire mesh comes down to performance.

As mentioned above, the natural high-temperature resistance seen in stainless steel alloys has been shown to hinder their weldability and hinder the effectiveness of heat treatment. In other words, you can overcome this obstacle by using low-carbon alloys.

In any case, if you weld your net, you should pay attention to the fact that the surface of stainless steel will change color when exposed to high temperature, because its heat resistance will not lead to high temperature oxidation.

Nickel does not have this problem because it does not have the same heat resistance. In fact, it is widely used because of its thermal conductivity, electrical conductivity and magnetic conductivity.

In addition, the corrosion resistance of nickel is excellent in special cases, such as exposing alloys to acid or lye applications. This is especially true when halides, caustic soda and various organic compounds are present.

评论

发表评论